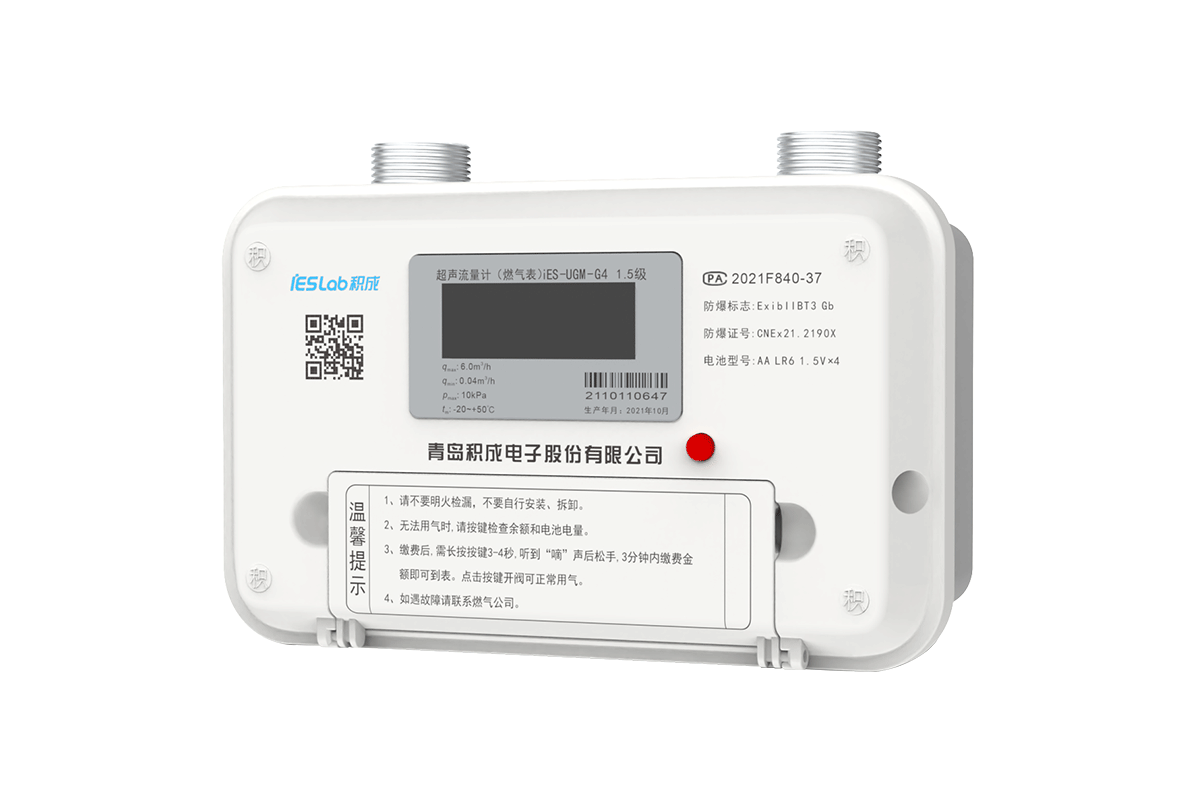

Ultrasonic gas meter

Key words:

Ultrasonic gas meter

Ultrasonic gas meter

Classification:

Product Description

Product introduction:

Ultrasonic gas meter is a fully electronic gas meter that uses the principle of time difference method for flow measurement. It has the characteristics of accurate measurement, wide range ratio, wide temperature adaptation range, small size, high reliability, and has the function of temperature and pressure compensation. The product adopts a fully independent research and development program to break the monopoly of foreign technology and realize the independent control of key technologies.

Product features:

• Accurate measurement: full flow point electronic calibration, high-precision correction

Range ratio width: 0.016~6 m/h wide range measurement

• Wide temperature adaptation range:-25~55 ℃ wide temperature range accurate measurement

Temperature and pressure compensation: real-time temperature and pressure compensation, reduce gas loss, reduce supply and marketing difference

Safety gas monitoring: it has a variety of gas safety warnings such as abnormal large flow gas consumption, slight leakage, continuous constant flow gas consumption, and no gas for many days.

• Small size: relatively small size membrane table, easy to install

• High reliability: fully electronic metering, no moving parts

Technical advantages:

• Independent research and development of ultrasonic flow channel

• Independent research and development of transducer

• Autonomous algorithm of domestic metering chip

• Independent research and development of flow verification equipment, sealing testing equipment, automatic production line

Technical parameters:

Parameter Class | Parameter Item | Unit | Model | ||

G1.6 | G2.5 | G4 | |||

Flow parameters | Minimum flow (Qmin) | m³/h | 0.016 | 0.025 | 0.04 |

demarcation flow | m³/h | 0.25 | 0.4 | 0.6 | |

Maximum flow rate (Qmax) | m³/h | 2.5 | 4 | 6 | |

| Accuracy class | 1.5 level | ||||

temperature and pressure compensation | temperature compensation |

| There are | ||

Pressure compensation |

| There are | |||

Pressure parameters | Maximum working pressure | kPa | 10 | ||

pressure loss | Pa | <250 | |||

Environment | Working temperature | ℃ | -25 ℃ ~ 55 ℃ | ||

Humidity range | %RH | ≤ 93% RH | |||

LCD display | Display digits |

| 9 | ||

Maximum display range (LCD display) | m³ | 999999.99 | |||

Minimum instantaneous flow (LCD display) | L/h | 0.1 | |||

Maximum instantaneous flow (LCD display) | m³/h | 99.999 | |||

Power supply (battery) | Battery Type |

| Dry battery (1 year) Built-in lithium battery (10 years) | ||

Measurement | Measurement method |

| Ultrasonic | ||

Valve | Valve control |

| Support remote valve control, can realize different permission valve control, including common off valve, authority off valve | ||

Valve closing time | Seconds | <1 second | |||

Durability |

| The number of continuous switching shall not be less than 10000 | |||

Communication mode | Communication mode |

| NB-IoT infrared bluetooth | ||

Base table | Base table |

| Steel shell/Aluminum shell | ||

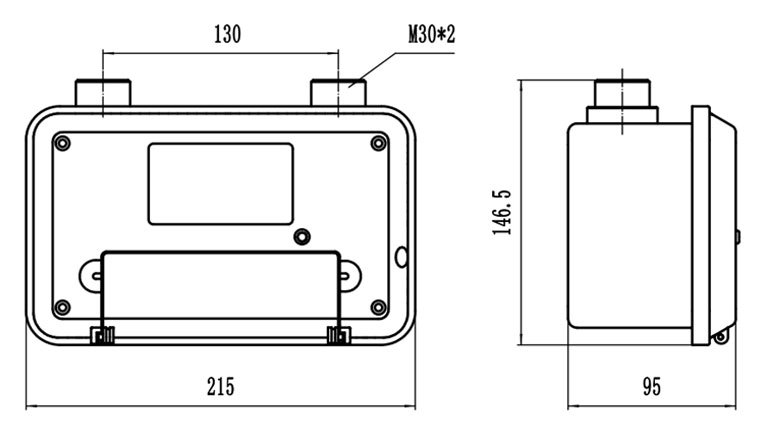

Thread |

| M30*2 | |||

Center distance | mm | 130 | |||

Whole machine protection | Protection level |

| IP65 | ||

Media Requirements |

|

| Air, natural gas | ||

Dimensional drawing

Related Products

Product inquiry

Filling in your phone and E-mail information will help us to get in touch with you in time and solve your problems as soon as possible.